Real-time composition

analysis of molten metals

Solutions for the whole metals value chain

Until now, process control in the metal industry has been limited by the need to manually cast a solid sample from the melt for off-line analysis, delaying the feedback of vital information about the chemical composition of the molten metal.

We at DTE are reshaping the global metal industry with technology that delivers real-time composition analysis in liquid metals, solving a decade long technical problem.

Our Solution

DTE’s LP-LIBS™ technology makes reference-grade elemental analysis directly from liquid metal in less than 60 seconds from sampling, delivering data with precision and accuracy.

Our Technology

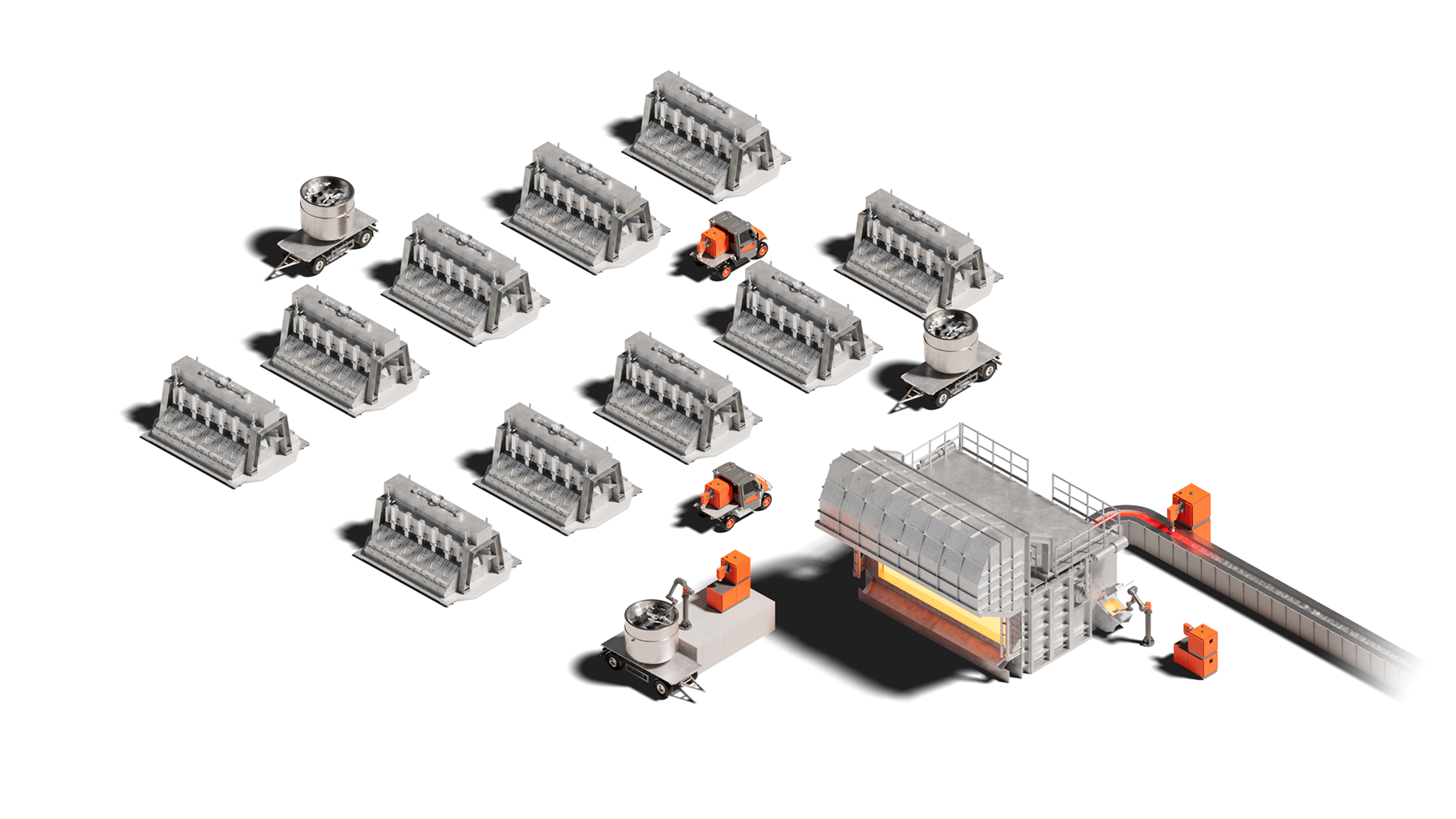

DTE’s solutions can be implemented at every process point where molten aluminum is handled, from primary smelters to recycling plants and end-user manufacturers.

Our Products

Real-world improvements in process efficiency, sustainability and safety for metal manufacturing and recycling.

Until now, process control in the metal industry has been limited by the need to manually cast a solid sample from the melt for off-line analysis, delaying the feedback of vital information about the chemical composition of the molten metal.

Watch DTE’s solution as featured on CBS NEWS

Want to know more?

Schedule a call with our expert team.