A new benchmark for elemental analysis of molten metals

Industry-leading LP-LIBS™ technology combined with our state of the art equipment solves decades-old industry problem by delivering instant elemental analyses directly from the molten metal into a user-friendly platform

Guaranteed Consistency

Comparable precision and accuracy to conventional laboratory analysis.

Reduced need for frequent standardization, even in harsh conditions.

Eliminates measurement uncertainty from the sampling process.

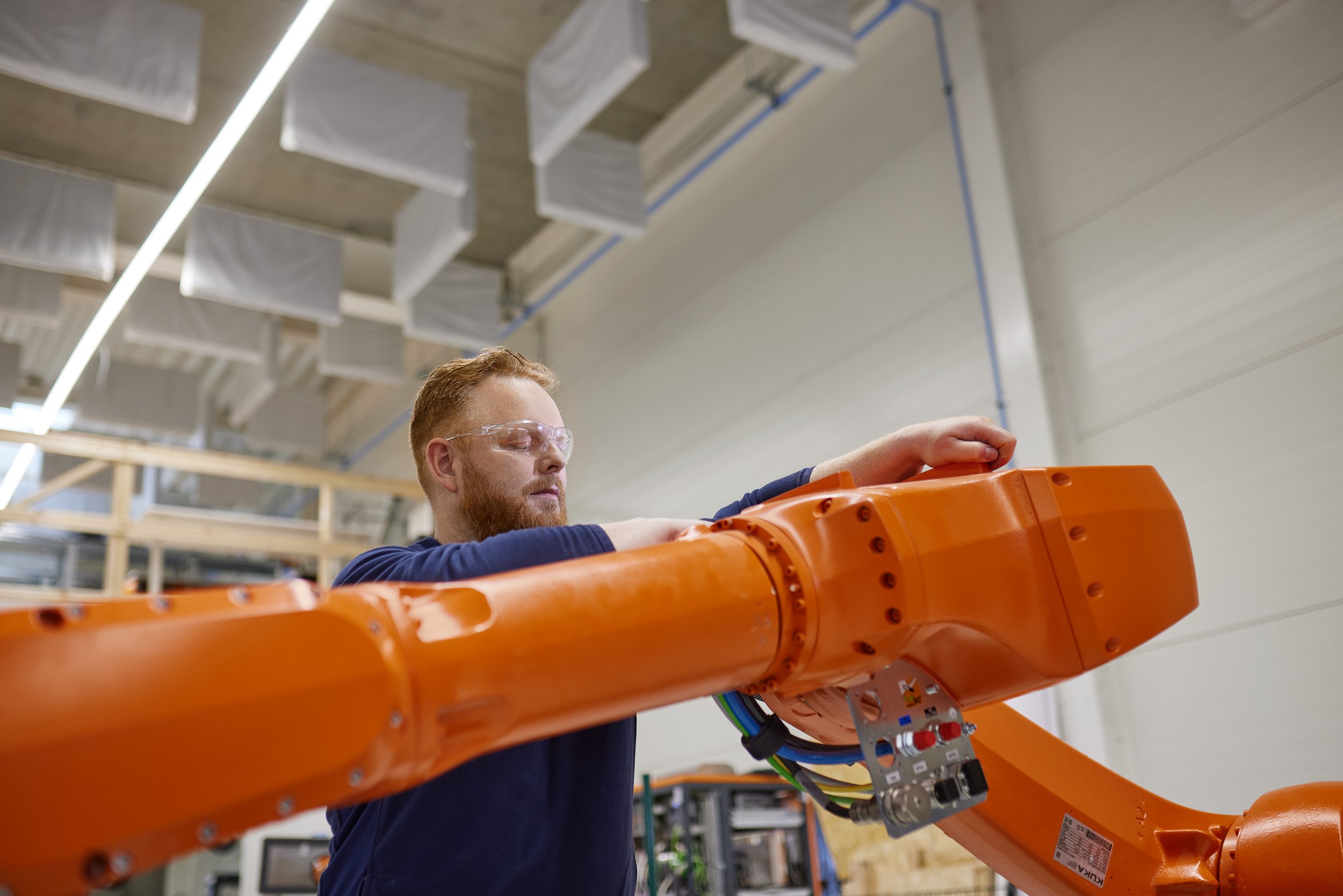

Improved Safety

Eliminates operator risk from exposure to molten metal.

Reduces the occurrence of burn injuries among plant operators.

Enhanced Process Insights

Provides comprehensive melt composition information from all critical process points.

Transforms data into high-value, predictive decision-making insights through a cloud platform.

Greener, Safer, and More Efficient Production

Reduces electricity consumption in metal production.

Minimizes scrap generation in aluminum casting.

Enables the creation of more valuable products in a more environmentally friendly and efficient manner.

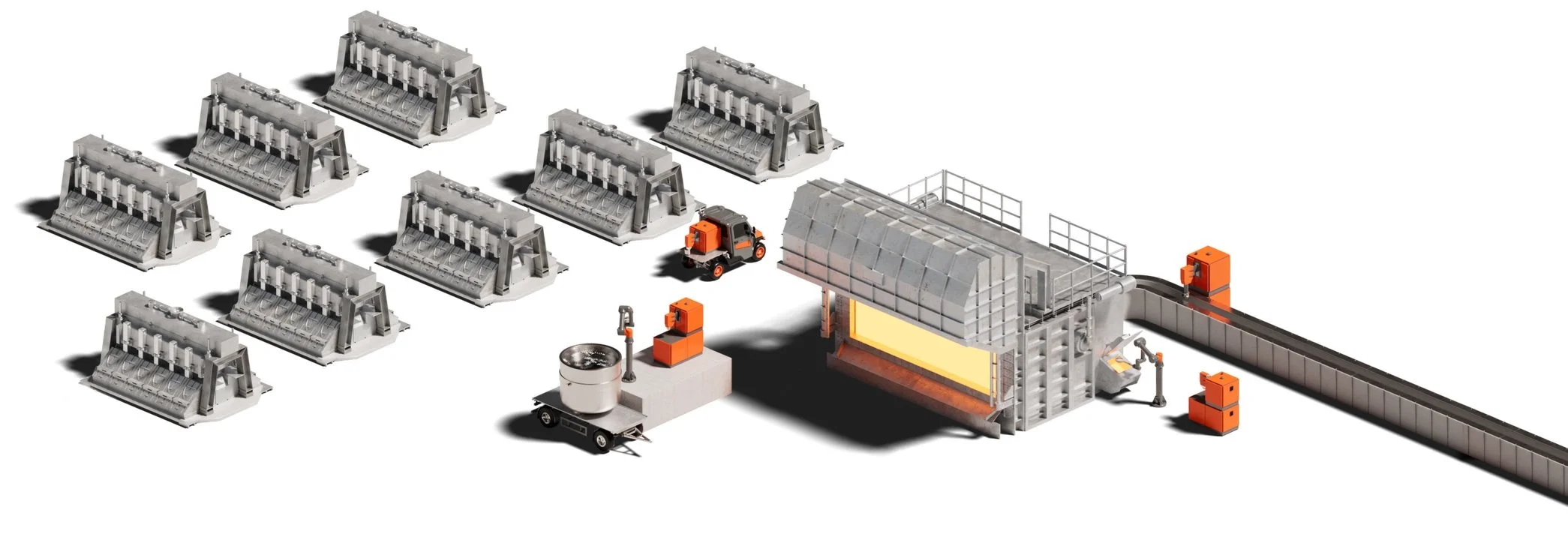

The right analyzer for any or all steps of the metals value chain

DTE’s solutions can be implemented at every process point where molten aluminum is handled:

In primary smelters

In secondary production

In end-user manufacturing

Potrooms, Crucibles, Furnaces, Launders

Explore our range of solutions to find the perfect solution for your needs.

Elemental analysis in a powerful platform

Our breakthrough LP-LIBS™ technology is uniquely able to deliver elemental analysis directly from liquid metal in less than 60 seconds from sampling. Seamless IT/OT integration combines our proprietary elemental analysis with a powerful analytics platform. This provides unprecedented real-time and predictive insights for process control.

Want to know more?

Schedule a call with our expert team.