Crucible Solution

Our crucible solution consists of connected stationary and fully automatic elemental analyzers and process intelligence platform, designed to streamline logistics in the casthouse production with live data, directly from liquid metal. The solution delivers immediate and precise composition information to casthouse operators and experts via real time, in situ reference quality analysis.

The Future Of Process Control is Real-Time

DTE’s crucible solution allows customers to optimize production processes by knowing exactly what is happening in the melt with real-time quality check of each crucible before batching.

Crucible solution benefits of implementation

Analyze Molten Metal in situ

Direct analysis of homogenous liquid metal.

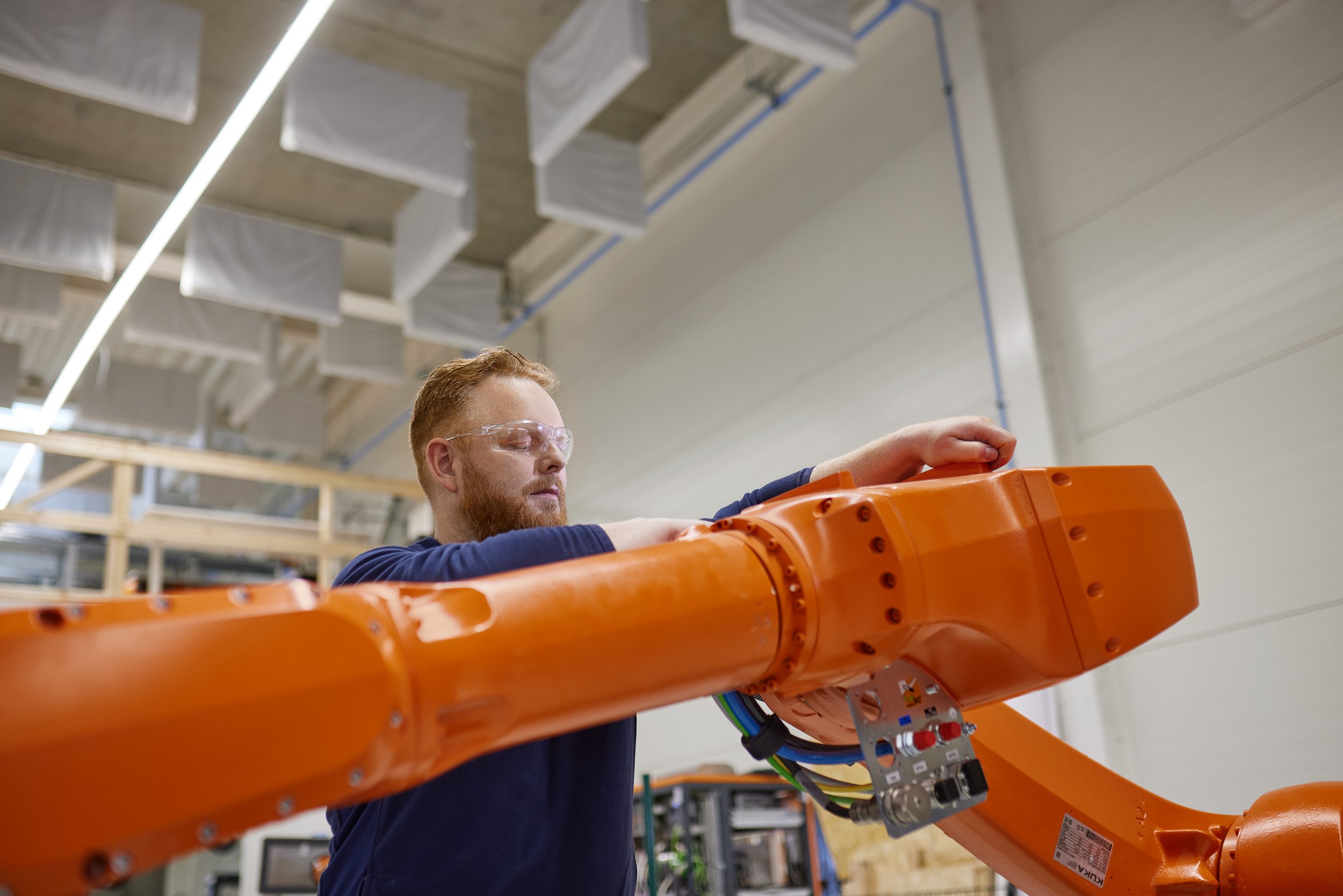

Automated sampling eliminates the need for manual sampling, increasing operator safety.

Improve Safety

Removing operators from handling molten metal samples not only eliminates one of the most hazardous tasks in the plant, as per recorded incidents, but also reduces plant traffic by eliminating the need to transfer samples to the laboratory.

Reduce Sampling Cost

Stop wasting operator time on handling physical samples and eliminate cost of operating and maintaining laboratory for sample preparation and analysis.

More Accurate Process Information

DTE's analysis technology correlates excellently with industry standards, offering superior accuracy through increased data points.

It ensures precise measurements in high-temperature industrial environments, replacing manual sampling entirely.

Maximize Quality

Our solution maximizes quality by tightening processing specifications with more datapoints, facilitating premium product production.

It also enables high sampling rates for full traceability, directing high-grade materials to specific uses.

Increased Throughput

Start casting faster, every time, comfortably within specs.

Enhanced decision-making leads to faster throughput, making the batch cycle time sorter.

Other Solutions

Potroom

Furnace

Launder

Want to know more?

Schedule a call with our expert team.